Food factory

The workshop for the supply of finished products. The sale takes place through delivery aggregators and supermarkets.

Task:

As a rule, production equipment has a relatively long service life in combination with strict regulatory requirements. This requires existing systems and processes to be digitally optimized.

Food production based on our technologies should accelerate current basic processes and productivity through advanced analytics, accurate data streaming and process monitoring.

We had to establish production management that would ensure transparency of production operations, accelerate the physical flow of production lines, increase the capacity of the workshop and the overall efficiency of equipment and people.

Completed works:

Audited the worksite as well as accounting and safety systems of food production.

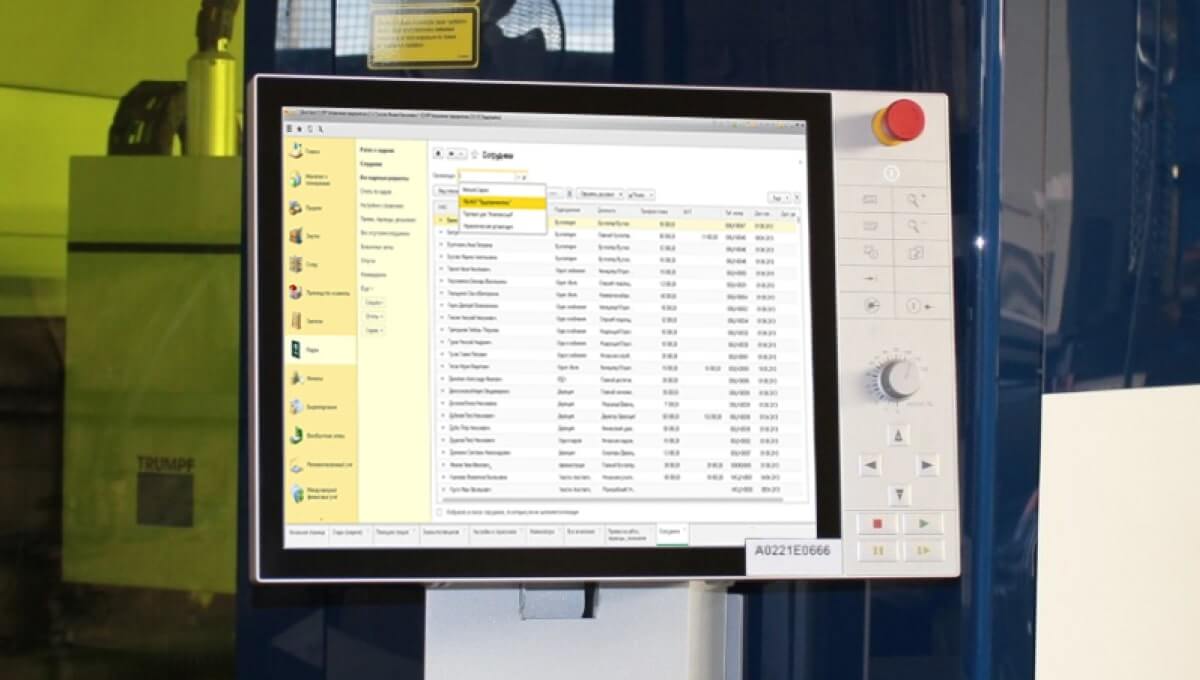

Finalized and implemented a software system for the accounting of raw materials and ready-to-use products.

Implemented an automated system for creating and storing flow charts.

Determined control zones for employees in order to eliminate shortages.

Implemented a warehouse and accounting automatic system and integrated it with the company’s ERP system.

Output:

Digital transformation has become a business driver of production. Deployment and integration of new technologies on the basis of the enterprise allowed to increase the efficiency of processes. We separated manual and automated processes with help of implemented IT solutions and improved them.